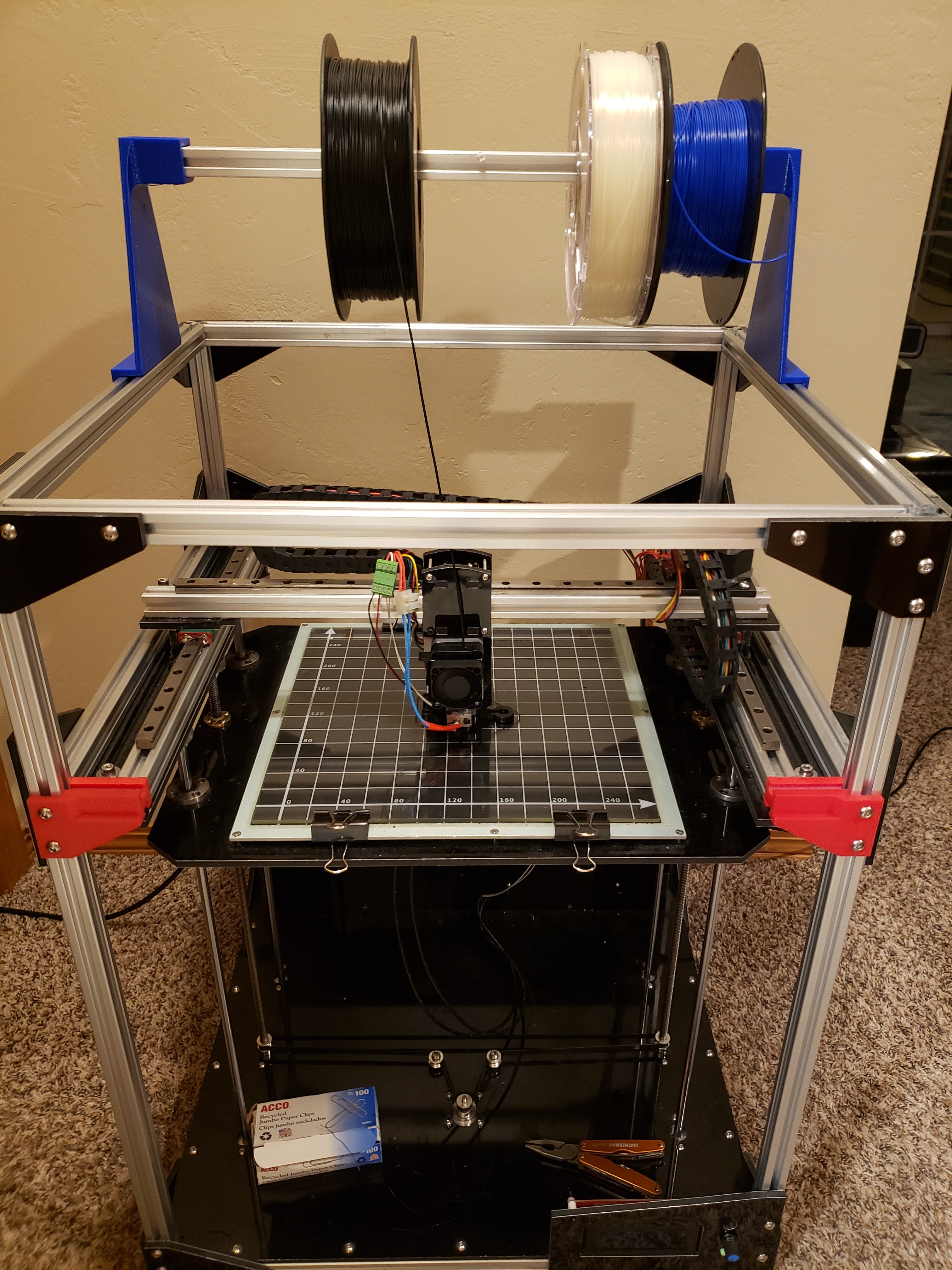

Folgertech FT-5 R2 Modifications

Aug. 14, 2022

Topics: 3D Printing

My workhorse 3D printer has been a Folgertech FT-5 for 4 years now. While it certainly has some issues, the now-defunct company made a pretty good printer. It came as a kit which required about two solid days of assembly, which was awesome because the owner gains an intimate understanding of it's inner workings and there was an abundance of extra parts left over.

Throughout the years I implemented the following upgrades:

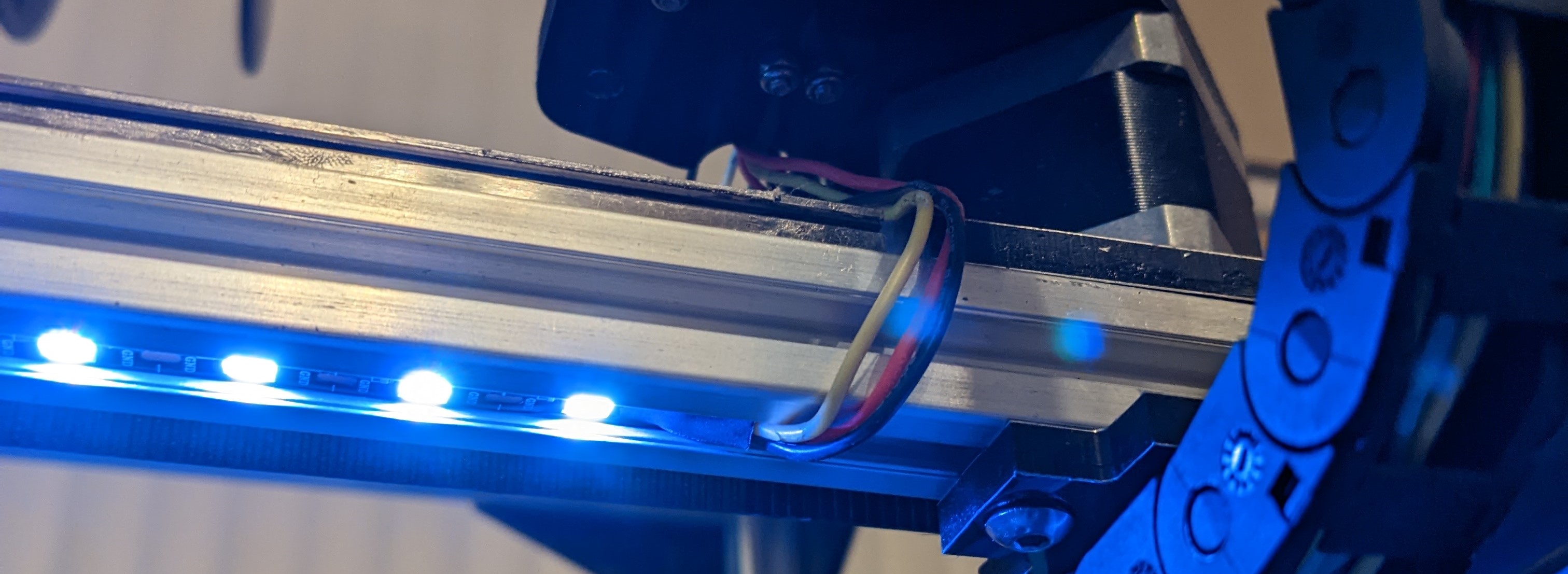

Neopixel Strip

Having a strip to light up the bed is a no-brainer. Plus, the strip will change from blue to red as the printer heats up! I just tucked the strip in the slot under the 8020 that forms the X-Axis carriage.

Better Filament Holder

I printed a couple of mounts to repurpose the 8020 that blocks access to the front of the print bread to hold the filament above the printer. Link to the parts on thingiverse here.

Better Heat Break

The heat break that came with the printer had two issues. First, there was no internal funnel to guide the filament in during a change, so it required a lot of fiddling around to get things working. The other thing was significant heat creep leading to partial clogs through long prints. Both of those problems were fixed by switching to this heat break. It has an internal funnel so swapping filament is a breeze, and it is lined with PFTE so heat creep is no longer an issue.

Custom Cooling Fan

The printer didn't come with a cooling fan, which seems like a HUGE oversight, to be honest. So I designed one! Link to the part on thingiverse here.

Dual Y-Axis End Stops

I ran in to an issue one day where the X and Y axis of my prints were not perpendicular. To fix this, I implemented a second Y-axis end stop so that any misalignment would be fixed after every homing move.

TMC 2209 Stepper Drivers

After switching to TMC 2209 stepper drivers I will absolutely never move back to the much more obnoxious A4988 drivers. TMC 2209's are much quieter, much stronger, and an easy swap. I would love the use the UART feature, but the MKS control boards don't allow it without some bodge wires which i'm not a fan of.